CANNABIS EXTRACTION EQUIPMENT

SKIP WINTERIZATION + DITCH DISTILLATION

THE PROX SENTINEL

ULTRA-COLD PROX OPERATION PROVIDES FOR IN-LINE WINTERIZATION

THE MPS WRAPS IT UP WITH CRYSTALLIZATION, FILTRATION, HTE SEPARATION & DECARBOXYLATION

The ProX SYSTEM, when integrated with our MPS PURIFICATION SYSTEM, transforms into what we proudly call the ProX SENTINEL—an unparalleled cannabis distillate and isolate production powerhouse with unmatched speed and ROI. This innovative system is engineered to seamlessly produce THC cannabis distillate, THCA isolate, CBD isolate, and other purified cannabinoids in-line. By maintaining a closed loop integrated process from start to finish, the ProX SENTINEL virtually eliminates contamination risks, ensuring the highest standards of purity and safety in a continuous batch process.

THE SENTINEL | STEP 1

THE PROX

HYDROCARBON EXTRACTOR

~85% PURE CANNABINOID PRECURSOR

CRUDE CANNABIS OIL EXTRACTION

THE PROX

- Four Standard Configurations (Scalable to ANY Size) to Match your Processing Goals (30 - 100+ lb per hour biomass processing)

- Ultra-Cold Temperatures Eliminate Need for Winterization (-112°F/-80°C and colder, rated to -300°F/-184°C)

- In-line Filtration for Removal of Pesticides, Heavy Metals, and other Contaminants

- Constructed of 316L Pharmaceutical Grade Stainless Steel to ASME BPE-2024 Standards for Bioprocessing (or 304 stainless steel for food and dietary supplements)

- PSI Certified for Use in all 50 States, CRN/EU/CE Ready

- GMP Compliant, meets or exceeds FDA cGMP and EU GMP / EudraLex Volume 4 GMP standards

- Precursor Extract for Production of Cannabinoid API, Isolate, Distillate, Diamonds / THCA, Sauce / HTE, Vapes, Shatter, Sugar, Crumble, Tinctures and Edibles

- Prodigy Manufactures Custom Pharma, Cannabis & Hemp Extraction and API Solutions with ASME Builds of Any Size

- First step in manufacturing of cannabinoid active pharmaceutical ingredients (APIs) and cannabis concentrate products

- Proudly MADE IN USA!

CRYTALLIZATION, DECARBOXYLATION & HTE SEPARATION

THE MPS

- THC, CBD, and Other Cannabinoid Isolation and Separation for the Production of 99%+ pure cannabis distillate, isolates, and active pharmaceutical ingredients

- Multiple Sizes to meet a broad scope of Production Goals, starting at 20, 60, and 100 liter vessels, expandable for any size operation

- Jacketed Isolation Column with Pneumatic or C1D1 Rated Power Agitation with Detachable 316L Lossless Yield Filter Basket with 25 Micron Filtration for Ease of API Capture

- Filtration Column with Numerous Centered Disc Filters and Option to Add Media to Remove Undesirable Compounds

- HTE (High Terpene Extract) Isolation and Separation with Fan Injection Column for Capture of Cannabinoid Terpenes

- Inline Decarboxylation and Solvent Purge

- Piped in Tandem with ProX Extractor for our Turnkey Flagship, the Prodigy's ProX Sentinel Cannabinoid API Continuous Batch Production System

- Constructed of 316L Pharmaceutical Grade Stainless Steel to ASME BPE-2024 Standards for Bioprocessing

- PSI Certified for Use in all 50 States, CRN/EU/CE Ready

- GMP Compliant, meets or exceeds FDA cGMP and EU GMP / EudraLex Volume 4 GMP standards

- Scalable for Pharma, Cannabis & Hemp Extraction and API Solutions with ASME Builds of Any Size

- Final Step in Manufacture of Plant-Based Cannabinoid APIs of at Least 99% Purity

- Proudly MADE IN USA!

THE SENTINEL | STEP 2 - 3

THE MPS

MULTIPURPOSE REACTION SYSTEM

~99%+ PURE CANNABINOIDS FOR THC CANNABIS DISTILLATE, THCA & CBD ISOLATE

CANNABIS DISTILLATE ROI CALCULATOR

(APPLICABLE TO ROI FOR PHARMACEUTICAL CANNABINOID ACTIVE PHARMACEUTICAL INGREDIENTS)

MINIMAL CAPX + OPERATIONAL TIME SAVINGS + REDUCED MAINTENANCE = UNSURPASSED ROI

SENTINEL | PROX | MPS

COMPLIANCE MATTERS

ASME | C1D1 | GMP | PSI

- Class 1, Division 1 (C1D1) compliant for all Type 6 & Type 7 licenses

- Engineer peer reviewed by PSI (Pressure Safety Inspectors), certified in all 50 states

- Technical Report and Field Verification included

- ASME-U Certified, NFPA 58 LPG, Closed-Loop Extraction System

- ASME BPE-2024 Standards for Bioprocessing

- NFPA 1 and IFC compliant

- Trans-fill approved per NFPA

- Meets or exceeds cGMP, 3A sanitary standards, and pharmaceutical GMP compliant

- Canadian CRN & European Union CE ready

- Food, Dietary Supplements, and Pharmaceutical GMP Compliant (FDA, EU, and worldwide compliance)

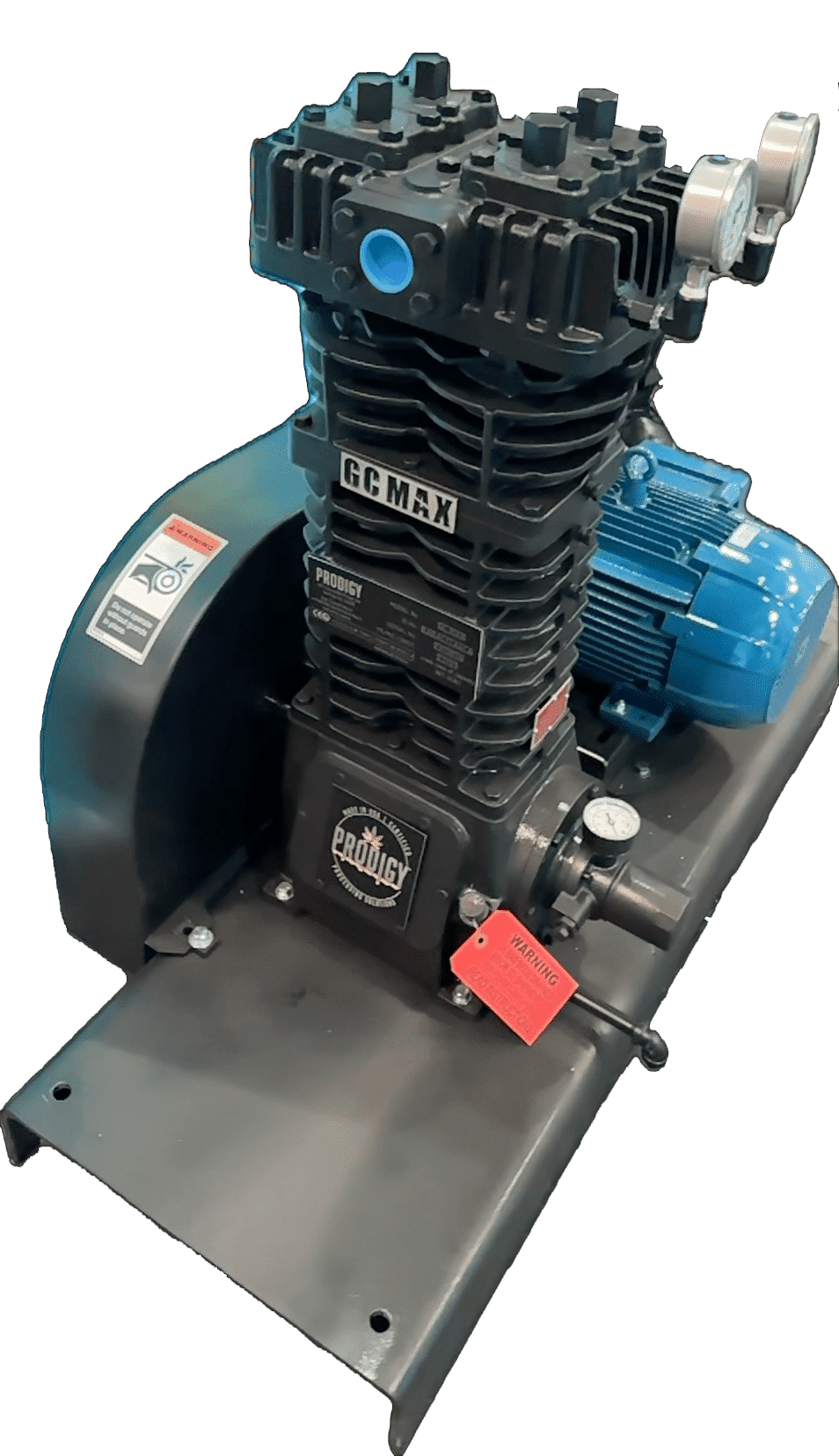

Oil-Free LPG Gas Compressors for Liquid Transfer and Vapor Recovery

C1D1 RECIPROCATING GAS COMPRESSORS

SUPERCHARGED ACTIVE SOLVENT RECOVERY WITH PRODIGY'S GC SERIES

Active solvent recovery in LPG (liquid petroleum gases), BHO and butane or propane cannabis extraction using a gas compressor is (often referred to as a solvent recovery pump) a process that assists in vapor recovery and efficiently recovers solvents used in the extraction of cannabinoids from cannabis material for adult recreational, medical cannabis, and pharmaceutical applications.

Depending on the specific setup, operating parameters, and other factors, active recovery can be up to 4-10 times quicker than passive operation. Active systems not only speed up the process but also are more efficient in solvent recovery, leading to less waste and lower operating costs over time.

All Prodigy GC Series gas compressors are equipped with a ductile iron head and cylinders, high-efficiency valves, steel pistons, self-adjusting piston rod seals and other robust features designed for quiet efficient handling of propane, butane, and anhydrous ammonia. Even under the most severe service conditions, the GC Series gas compressors offer the best-combined characteristics of sustained high-level performance, energy efficiency, trouble-free operation and low maintenance cost.

-60°C to -100°C CHILLERS

The Next Generation of Ultra Low Temperature and Cryogenic Cannabis, Hemp, Biomedical and Pharmaceutical Chillers

Thermonics® leads the industry in low (-60.0°C) and ultra-low temperature (-100.0°C) chillers for cooling fluids and gasses in process cooling applications. Our chiller systems include fluid chillers, gas chillers, and cryogenically cooled (LN2, LCO2) chillers. Systems are available in 9 water-cooled models, 9 air-cooled models, and an LN2 (Nitrogen Chiller) model. All models compatible with a variety of heat transfer fluids.

Temperature Ranges from -100°C to +300°C

Cooling Capacities up to 30kW

Air or Water Cooled Condensers

ANCILLARY & POST Processing Equipment

C1D1 ENCLOSURES, MODULAR CLEAN ROOMS, Vacuum Ovens, Wiped-Film Distillation, Analytical Testing, Chillers, Freeze Dryers for Cannabis & HEMP Extraction

Best in class vacuum ovens, C1D1 blast proof rooms, clean room enclosures, distillation equipment, freeze driers, temperature control units, testing and analytical devices and more from the world’s top extraction technology suppliers. Everything you need for the production of the highest quality cannabis concentrates, HTE, budder, wax, isolate, distillate (for a variety of uses including vape cartridges), gummies, THCA, and many other hemp and cannabis consumable products.