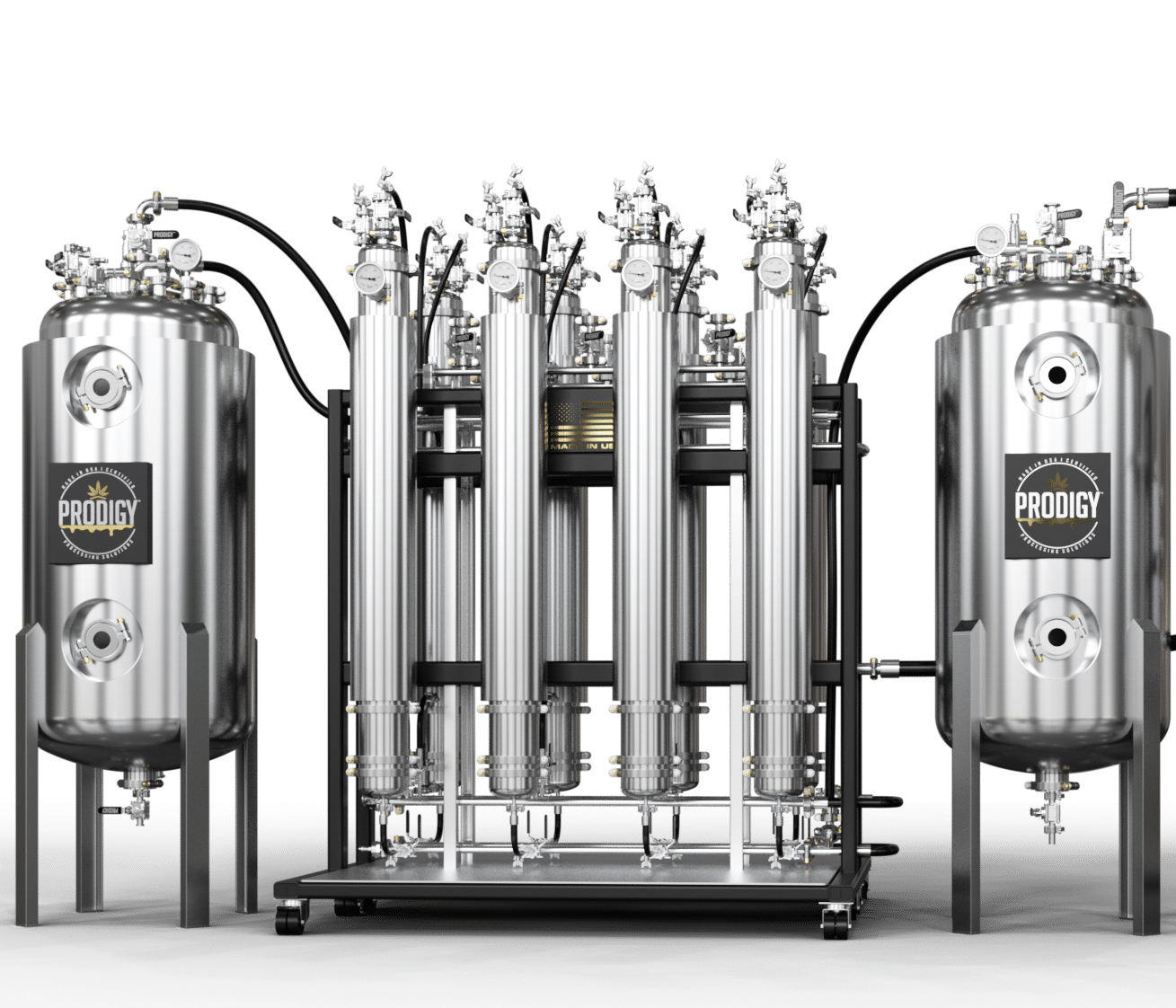

GMP compliant extraction equipment from Prodigy Processing Solutions embodies the pinnacle of precision, safety, and regulatory compliance. Designed to meet or exceed stringent FDA cGMP and EU GMP standards, and other regulatory bodies throughout the world such as Health Canada and the European Medicines Agency (EMA), our state-of-the-art systems ensure optimal performance and reliability for pharmaceutical-grade cannabis extraction.

Navigating the complex landscape of GMP regulations may seem challenging, but with expert guidance, the process becomes very manageable and seamless to integrate into your cannabis lab or pharmaceutical manufacturing facility.

PRODIGY offers comprehensive, turnkey solutions that include everything from facility design to GMP-compliant equipment and standard operating procedures (SOPs) with ongoing product support. Prodigy’s one-stop-shop approach ensures that every aspect of your cannabis extraction lab or cannabinoid pharmaceutical manufacturing facility meets FDA cGMP, EU GMP, and state marijuana board regulatory standards. Whether you’re starting from scratch or upgrading an existing operation, our expertise provides you with seamless, end-to-end solutions that guarantee your operations are efficient, compliant, and ready for success.

Discover how Prodigy Processing Solutions can help you achieve GMP Compliance with our comprehensive, turnkey solutions tailored to your specific needs. Explore our resources and services to ensure your operations meet the highest standards of quality and safety.

PRODIGY adheres to the globally recognized ASME BPE (Bioprocessing Equipment) standard, established by the American Society of Mechanical Engineers (ASME), which provides comprehensive guidelines for the design, manufacturing, testing, and inspection of bioprocessing equipment used in industries such as pharmaceuticals, biotechnology, and other sectors requiring sterile processing.

This standard ensures that equipment used in the production of biopharmaceuticals adheres to stringent sanitary and operational requirements, focusing on materials, surface finishes, and cleanability to support Good Manufacturing Practice (GMP) compliance. The goal of ASME BPE is to ensure the safety, consistency, and quality of products while minimizing contamination risks in high-purity environments.

A wide range of industries and professionals rely on ASME BPE standards for high-purity processing. Pharmaceutical companies depend on it to ensure that their equipment meets the strict requirements for producing sterile drugs and biologics. Biotechnology firms use ASME BPE standards for manufacturing critical products such as vaccines, gene therapies, and other biotech innovations, where sterility and ease of cleaning are vital to maintaining product safety.

Equipment manufacturers also adhere to ASME BPE standards to meet regulatory requirements and ensure that their products are both safe and compliant. For Contract Manufacturing Organizations (CMOs) and Contract Research Organizations (CROs), ASME BPE-compliant equipment is essential for producing high-purity products in accordance with GMP regulations.

**Because ASME BPE is the highest echelon of GMP compliance, it also meets and exceeds state cannabis GMP requirements, FDA, and worldwide GMP standards for food, dietary supplements, and nutraceutical processing.**

Regulatory agencies like the FDA and EMA reference ASME BPE during facility inspections to verify compliance when approving pharmaceutical and biopharmaceutical manufacturing sites. Process engineers and designers leverage these standards to ensure that the equipment they develop is not only optimized for performance but also easy to maintain, hygienic, and free from contamination risks.

In summary, the ASME BPE standard is critical for ensuring that equipment used in high-purity processing environments is designed and operated in a way that supports the stringent requirements of GMP and regulatory compliance, protecting the safety of products and consumers alike.

Designed to support clients aiming for GMP compliance — including FDA cGMP, EU GMP, and worldwide GMP regulatory standards — PRODIGY’s GMP Equipment Documentation Package includes a comprehensive set of detailed documents that are invaluable for meeting the stringent requirements of FDA cGMP and EU GMP associated with audits and inspections. PRODIGY assembles this extensive set of documents including, as applicable, material certifications with full traceability for all required equipment components, cut sheets, required utilities, installation drawings, manufacturer generated URS (User Requirement Specification), top level PNID (piping and instrumentation diagram) and assembly drawings, operation manuals with maintenance requirements and procedures, critical spare parts list, equipment instrument list, and manufacturer certification of PRODIGY’s IQ/OQ/PQ (Installation Qualification, Operational Qualification, and Performance Qualification) validation and adherence to protocols per USP (United States Pharmacopeia) and international standards.

PRODIGY is dedicated to providing GMP-compliant cannabis extraction and cannabinoid bioprocessing systems that meet or exceed the expectations of regulatory agencies worldwide. From initial design to final validation, every step of our manufacturing process is guided by Good Manufacturing Practice (GMP) principles, ensuring our equipment meets the most rigorous global standards. Whether serving the pharmaceutical, biopharmaceutical, or cannabis industries, our solutions provide our clients with the compliance, reliability, and performance they need to succeed in regulated markets worldwide. Prodigy meets or exceeds the regulatory requirements for GMP compliant cannabis extraction equipment in Australia, Uruguay, Colombia, Argentina, Brazil, Canada Germany, Luxembourg, Malta, Netherlands, Czechia (Czech Republic), Portugal, North Macedonia, Greece, Spain, and the United Kingdom (UK), providing our customers total compliance for the European cannabis industry and beyond.

The European equivalent to the U.S. Food and Drug Administration (FDA) is the European Medicines Agency (EMA). The EMA is responsible for the scientific evaluation, supervision, and safety monitoring of medicines in the European Union (EU). Like the FDA, the EMA plays a critical role in ensuring that all medicines available on the EU market are safe, effective, and of high quality.

Unique EU and other European nations' Good Manufacturing Practices (EU GMP) requirements for cannabis extraction equipment mandate stringent controls over manufacturing processes, ensuring that equipment is specifically designed and validated to prevent contamination and guarantee consistent product quality and safety across the European market.

PRODIGY's EU GMP compliant cannabis extraction and cannabinoid pharmaceutical manufacturing equipment meets or exceeds domestic and international standards. Our state-of-the-art cannabis processing equipment ensures the production of safe, reliable, and potent recreational and medicinal cannabis products, including food, dietary supplements, and pharmaceutical. PRODIGY is committed to global regulatory compliance and consumer safety in the cannabis and biopharma industries.

The Conformité-Européenne (CE) symbol signifies that a product complies with all applicable European Union (EU) regulations and directives for health, safety, and environmental protection standards. This mark indicates that the product is allowed to be legally sold within the European Economic Area (EEA). The CE mark conveys to government officials that the product can be legally placed on the market in their country and to customers that the product safely meets EU standards.

IECEx certification is imperative to promoting global industrial safety by establishing standardized practices for the design, testing, and certification of equipment used in explosive environments. To help make such environments safe, IECEx provides a means for manufacturers, regulators and users of equipment in hazardous areas to address the risk of fires or explosions from flammable gases. Testing and certification of equipment, services and competence of persons to international standards facilitates the sale of safer products internationally at a lower cost.

The ATEX symbol indicates that a product conforms to the ATEX directives of the European Union, which are aimed at ensuring the safety and health of workers in potentially explosive atmospheres. ATEX stands for "Atmosphères Explosibles." The symbol is used on equipment and protective systems intended for use in explosive atmospheres, covering a broad range of products, including electrical and mechanical equipment, protective systems, and components.

At Prodigy Processing Solutions, we understand the critical importance of adhering to Canada's rigorous food, natural health products (NHPs), and pharmaceutical manufacturing standards. Health Canada is the primary regulatory body for pharmaceuticals and natural health products in Canada. Prodigy's GMP-compliant extraction equipment is meticulously designed to meet and exceed the guidelines set forth by Health Canada, including the Natural Health Products Directorate (NHPD), ensuring that our clients can confidently achieve compliance with national regulations.

Design and Validation

Our equipment is engineered with precision to prevent any negative impact on product quality. This includes using materials that do not react with, contaminate, or alter the product in any way. Each component is selected and constructed to ensure robustness and reliability, essential for the consistent production of pharmaceutical products.

Ease of Cleaning and Maintenance

Recognizing the importance of cleanliness in pharmaceutical production, our systems are designed for easy cleaning and maintenance. Smooth surfaces, minimal crevices, and easily accessible parts allow for effective cleaning and sterilization processes, reducing the risk of cross-contamination and ensuring compliance with Health Canada’s stringent sanitation standards.

Documentation and Compliance

We provide comprehensive documentation for all our equipment, covering installation, operation, and maintenance procedures that align with the Good Manufacturing Practices (GMP) guidelines. This documentation is crucial for audit readiness and regulatory inspections, helping our clients navigate the complexities of compliance with confidence.

Adapting to Canadian and International Standards

Prodigy’s extraction systems not only meet Health Canada’s GMP requirements but are also designed in compliance with international standards, including those set by the FDA and EU GMP. This dual compliance ensures that our clients can expand their operations globally without compromising on quality or regulatory obligations.

If you are looking to purchase GMP compliant extraction equipment in Alberta, British Columbia, Manitoba, New Brunswick, Newfoundland and Labrador, Nova Scotia, Ontario, Prince Edward Island, Quebec, or Saskatchewan, we're ready to provide you compliant and cost-effective extraction equipment solutions.

By choosing Prodigy Processing Solutions, you are partnering with a leader in extraction technology that is committed to quality, safety, and compliance, ensuring your pharmaceutical production meets the high standards expected by Health Canada and other global regulatory bodies.