InTEST Thermal Solutions’ Thermonics® line of temperature control units leads the industry in low (-80.0°C) and ultra-low temperature (-100.0°C) chillers for cooling fluids and gasses in process cooling applications. Our chiller systems include fluid chillers, gas chillers, and cryogenically cooled (LN2, LCO2) chillers. Systems are available in 9 water-cooled models, 9 air-cooled models, and an LN2 (Nitrogen Chiller) model. All models compatible with a variety of heat transfer fluids.

Thermonics Cryo Chillers use liquefied cryogens (LN2 to cool heat transfer fluids with a proprietary cooling technology, delivering low and ultra-low temperatures and rapid transitions rates to a test device or process.

Cryo Chillers are compact, portable systems ideal for both ultra-high and variable capacity cooling applications where supply of LN2 or LCO2 is automatically adjusted by the chiller’s control system to meet the specified cooling requirements.

Intended for perfect pairing with the ProX 20 and ProX 40, the inTEST 5kW ProChill Dual Stage Cascade Liquid Chiller provides: Temperature Range -80°C to +25°C • Cooling Capacity 5000 watts @ -80°C • 8 GPM @ 50 psi @ 60 HZ magnetically coupled turbine pump • VFD for Programmable Fluid Pressure • Anti Backflow Fluid Circuit• 10 gallon internal fluid expansion tank • 1800W @ 220V heater • 480V, 3 phase 60 HZ power

Offered in 5.0kW / 17,000 BTU/hr / 1.42 tons of refrigeration (RT), 7.5kW / 25,000 BTU/hr / 2.13 RT, 10.0kW / 34,000 BTU/hr / 2.84 RT, and 12.5kW / 42,000 BTU/hr / 3.55 RT @ -80°C configurations for pairing with the ProX 60 and 80 and other hydrocarbon and ethanol extraction equipment configurations.

Made in USA by inTEST Thermal Solutions • Powered by Prodigy

Thermonics chillers originated as customized solutions for demanding applications within the Mil/Aero and Energy industries. They have leveraged that engineering expertise to produce a family of chillers delivering the highest quality and fastest pull-down times available in the botanical extraction industry. Our cooling systems are ideal for large scale industrial cannabis manufacturing and small run, startup processing. We can help you get colder, faster to increase your cannabis processing throughput

PERFECT for pre cooling of material socks for cannabis extraction, rapid winterization for the removal of fats, waxes and lipids, fresh frozen material storage, and more

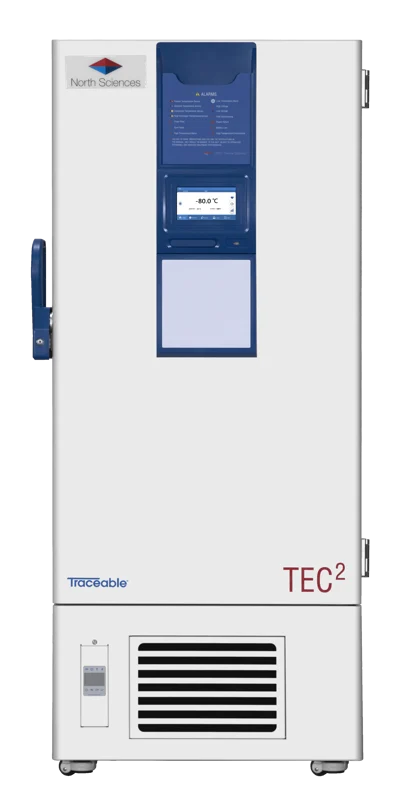

SAFEST TWINCORE™ BASED TECHNOLOGY employs 2 Core, 2 refrigeration system, 2 control commands for Compressors, enabling one to maintain temperature if the other is disabled, unparalleled safety

FAST Dual Cooling system enables the fastest pull down (4.5hr) & door opening recovery times (80min) after 2min door opening

TIGHTEST UNIFORMITY industry best +/-2.5C uniformity ensures your samples are being stored within the proper temperature range to maintain integrity

GREATLY reduced frost development on the inner compartment doors due to interlocking gasket design and heated door seal

MORE ULT Storage on your Floor Space, 50-90% more samples in the same space

UNIQUE revolutionary dual core refrigeration system

NEW HANDLE Lockable Door Handle for easy access

EASIEST to use, color 7’’ touchscreen panel allows full user control

HANDIEST USB PORT makes transferring logged data to a PC simple and convenient. Important information such as freezer temperature, door opening times and alarm history is logged for monitoring in GLP applications

BEST INSULATION Combining vacuum insulation panels with high efficiency dual layered insulated inner doors ensures longest cold retention and pull-up times. Ensures optimum temperature uniformity, while reduced wall thickness maximizes storage capacity and reduces energy usage by 40%