With increasing scrutiny on consumer safety of cannabis products coupled...

Read More

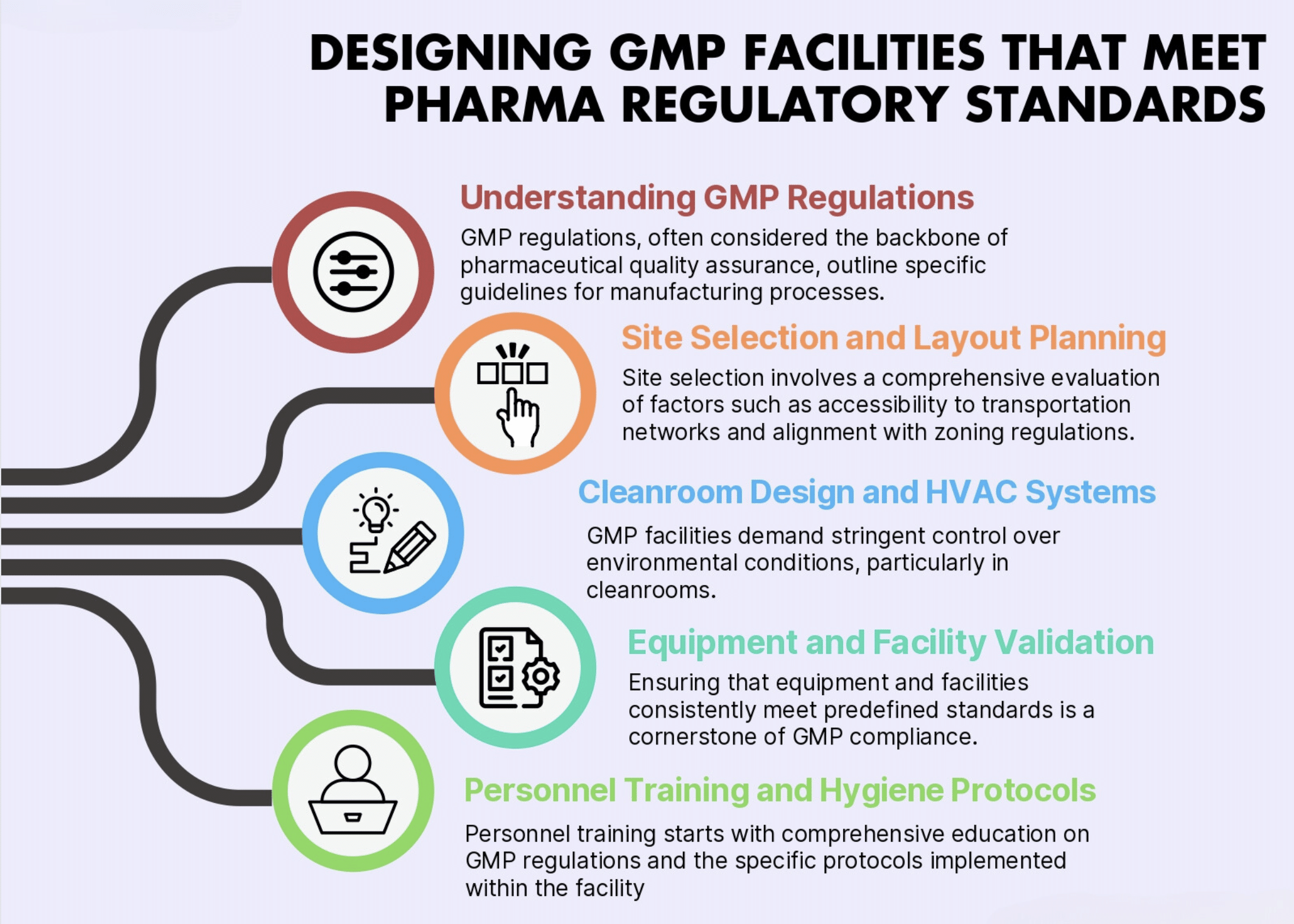

Whether or not your lab is processing cannabis for food, dietary supplements, nutraceuticals, or pharmaceuticals, your equipment and processes necessitate adherence to GMP quality standards and sound business decision protocols. The equipment you choose for your cannabis extraction business is crucial for the success and longevity of your operation, from avoiding product liability to garnering amazing profitability, it matters.

Here are some key points to consider when deciding what equipment to work with for your cannabis extraction business.

These mistakes can lead to regulatory non-compliance, operational inefficiencies, quality issues, and increased costs. To avoid these pitfalls, companies should carefully consider all aspects of 21 CFR 211.63 when designing or selecting manufacturing equipment.

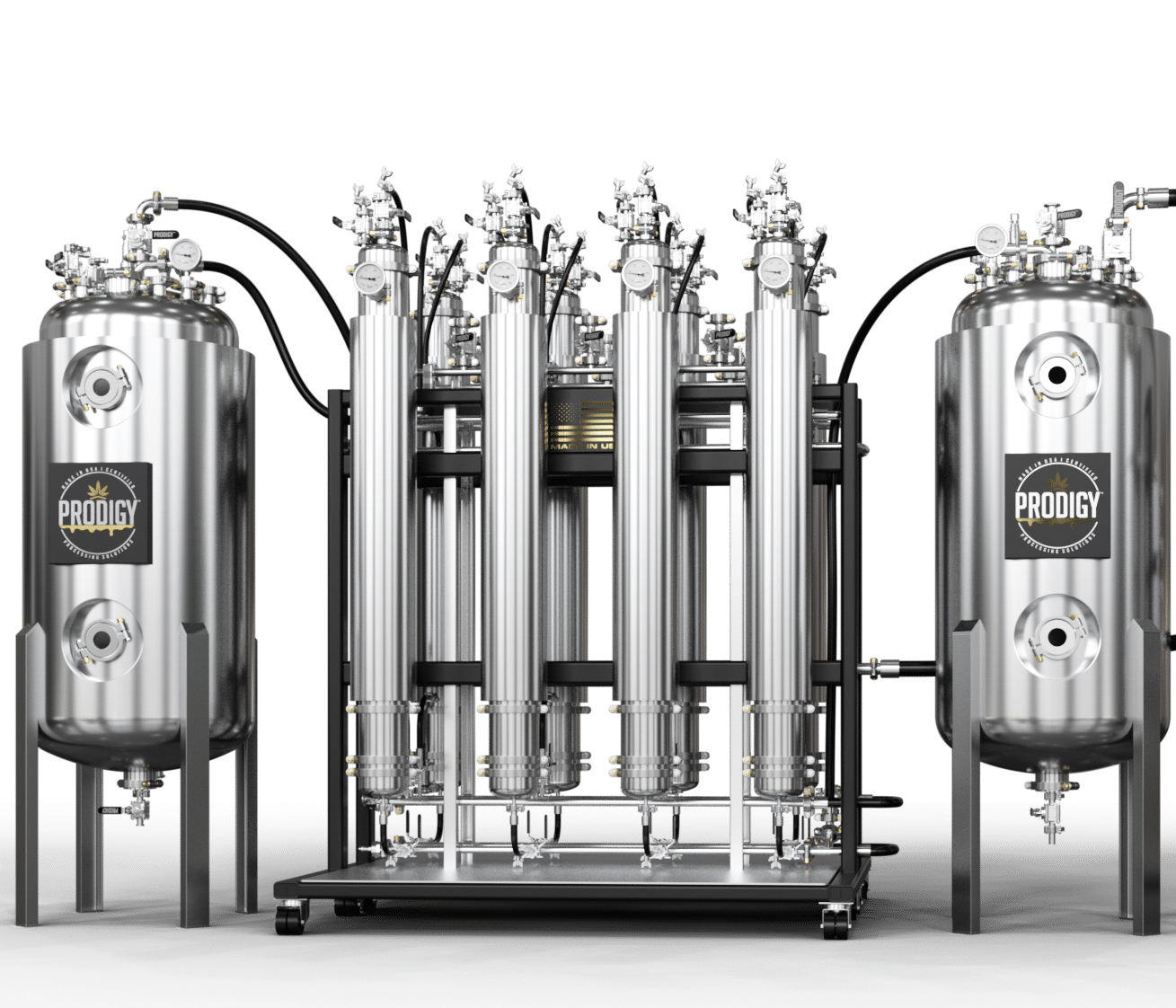

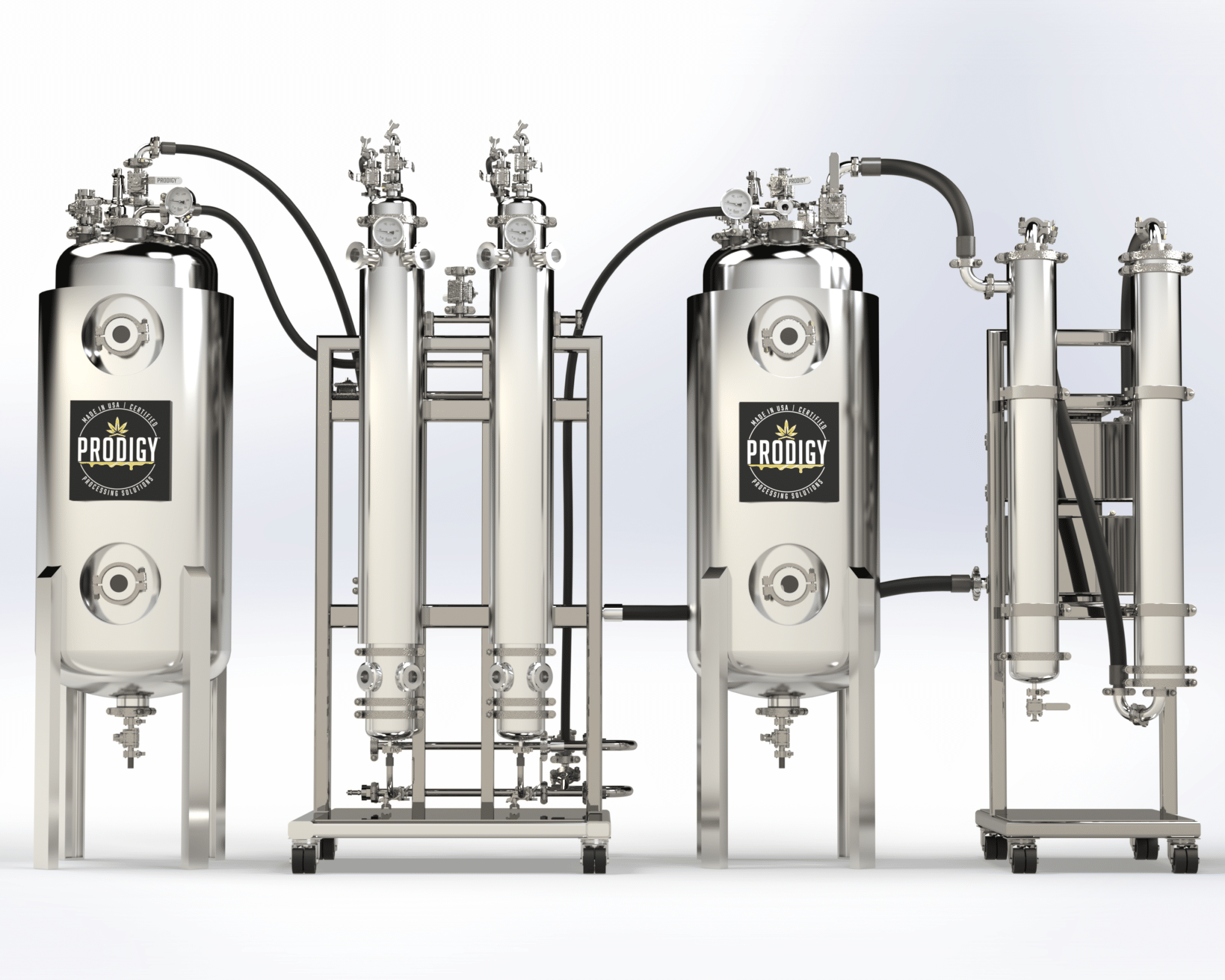

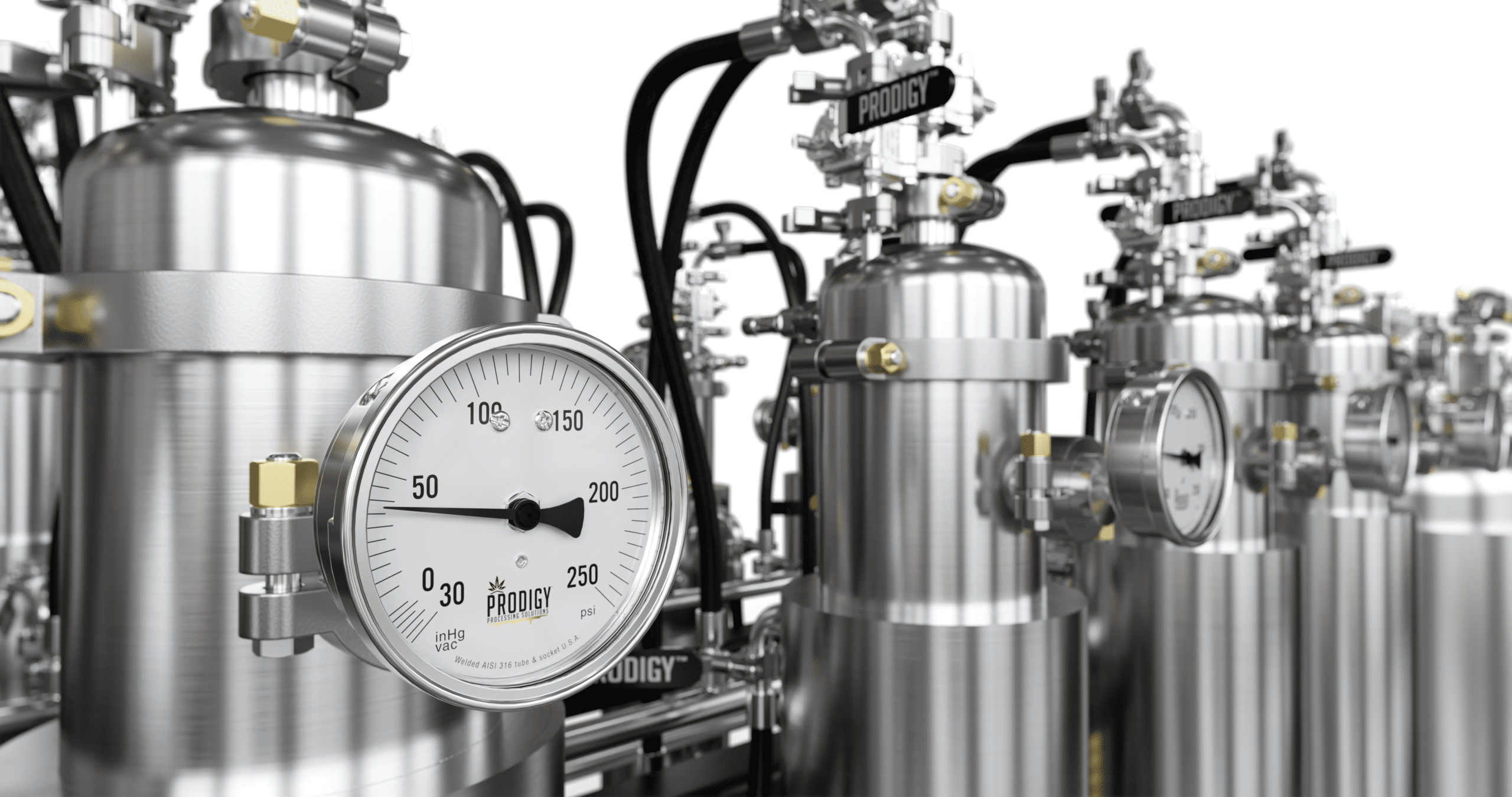

PRODIGY addresses these common flaws of other cannabis extraction equipment manufacturers by incorporating advanced design principles, innovative advanced engineering, and industry foresight, while ensuring optimal performance, compliance, and scalability for maximum profitability and return on investment.

PRODIGY goes beyond just meeting industry standards by offering innovative, compliant, and adaptable cannabis extraction equipment that addresses the shortcomings of other manufacturers, ensuring that businesses can operate at peak efficiency while maintaining the highest levels of safety, scalability, and GMP compliance.

In short, our customer’s success is our success!

Crude Oil / Precursor Extract | Chemical Isolation, Separation, and Purification | Filtration / HTE (Terpene) Separation | Wiped Film Distillation | C1D1 and C1D2 Rooms | Clean Rooms | Freeze Dryers | Analytical Testing | Equipment Installation and Training | Turnkey Extraction Solutions from Plant to 99%+ Cannabinoid API

Full Design-Build Services for Cannabinoid Pharmaceutical Manufacturing Full Facility Design | GMP Compliant Lab Design | FDA cGMP | EU GMP | Worldwide GMP | Architectural Drawings | MEP Plans | Construction Documents | Construction Services

Basic Crude Extraction (cannabinoid precursors) | Distillate Production | Isolate Production | Cannabinoid APIs | Delta-9 THC (plant-based Dronabinol i.e., tetrahydrocannabinol) | CBD (cannabidiol) | CBDV (cannabidivarin) | THCV (tetrahydrocannabivarin) | CBN (cannabinol) | CBG (cannbigerol) | And more cannabinoid APIs of 99%+ purity

Legal & Regulatory | GMP Compliance | Standard Operating Procedures | Food, Dietary Supplements, and Pharmaceutical SOPs | Safety Protocols | Business / Revenue Opportunities | Maximizing Optimization, ROI and Profitability

World Class GMP Compliant Cannabis Extraction Technology

The Professional's Choice for Cannabis Extraction

With increasing scrutiny on consumer safety of cannabis products coupled...

Read MoreWith increasing scrutiny on consumer safety of cannabis products coupled...

Read MoreWith increasing scrutiny on consumer safety of cannabis products coupled...

Read More